Daily Archives: 10/31/2017

Ultrasonic Cleaning System

How it works

The Fluid Dynamics Ultrasonic Cleaning System has over 250 pizeo ceramic transducers bonded to the bottom and both ends of the tank. These transducers have the unique property of changing size almost instantly when excited by an electrical signal sent by the seven generators we use to power the transducers. When excited each transducer increases in size and causes the internal bottom and sides of the tank to move creating compression waves in the chemical solution.

By using electrical generators that put out high frequency signals (from 20 kHz to 250 kHz) the transducers rapidly induce what are called compression and rarefaction waves in the solution -‘rarefaction’ reduces density and is the opposite of ‘compression’ which increases density.

During the rarefaction cycle the liquid is literally torn apart creating vacuum cavities within the solution. These cavities grow larger and smaller as the compression waves are continued and when the cavities reach a certain size, which is dictated by the frequency and the wattage of the signal, they can no longer retain their shape. Once they reach this point the cavities violently collapse and create a temperature of about 5,000oC with a jet of plasma that collides against whatever object is in its way at a speed of about 800 km/h. Every second there are literally millions of these cavities being created and collapsed – particularly when you have the power of over 250 transducers working together in the heated chemical-laden solutions we use at Fluid Dynamics.

The collapsing of the cavities is what cleans the parts. The jet of plasma will explode the contaminant, or any other material, off the surface without damaging the surface, and by adding the right chemicals to the solution at the correct temperature, the effectiveness of the cleaning operation is increased even further.

The cleaning power of ultrasonics depends on the collapse of the vacuum cavity being violent. If there is any gas in the solution that gas will migrate to the vacuum cavity (the area of least pressure), reduce the violence of the collapse and, in turn, reduce its cleaning power. By heating our solutions and thoroughly degassing them we drive out any trapped gas, enhancing the violence of the cavity’s collapse and further improving the ultrasonic cleaning process.

We also ensure the parts do not touch the sides or bottom of the tank as that interferes with the creation of ultrasonic energy and reduces its effectiveness – just like putting your finger on a sound speaker interferes with the creation of sound.

Vehicle Pollution Management Equipment

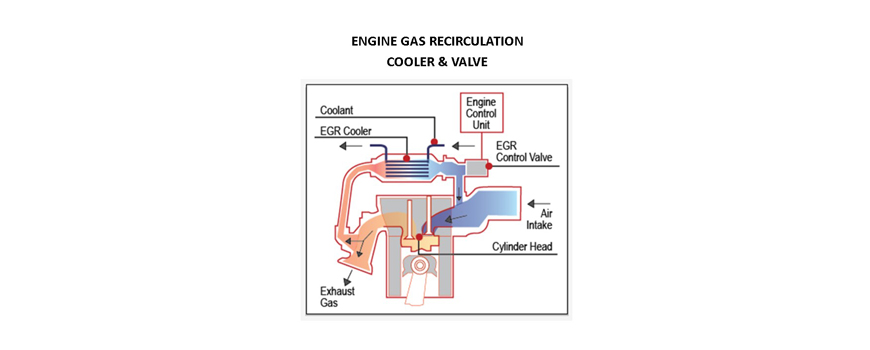

What are Exhaust Gas Recirculation (EGR) systems?

Exhaust Gas Recirculation (EGR) systems are anti-pollution devices used commonly in diesel engines that reduce the amount of Nitrogen Oxide (NOx) that is emitted through a vehicles exhaust. The engine’s combustion process produces Nitrogen and as the engine’s temperature rises, that Nitrogen chemically combines with the Oxygen in the engine’s combustion chamber and forms NOx which, in turn, forms smog when it reacts with sunlight. The EGR functions by recirculating the engine’s exhaust in a controlled manner back through the engine and the EGR valve acts as the tap that that controls the flow of the exhaust. The EGR allows oxygen depleted exhaust to enter the intake system, control combustion and reduce NOx.

What is an Exhaust Gas Recirculation (EGR) Valve?

EGR valves keep vehicle emissions to a minimum and ensure that vehicles do not pollute the atmosphere. To do this efficiently it is important to keep EGR valves clean and understand what signs to watch for to determine when it is time to clean, refurbish or replace it.

Benefits of EGR Valves

EGR valves take much of the gas that would otherwise escape out the exhaust and it recirculates it. The valve pushes the exhaust gas back into the intake manifold to allow the engine to burn the gas further saving on fuel and keeping the gas out of the atmosphere.

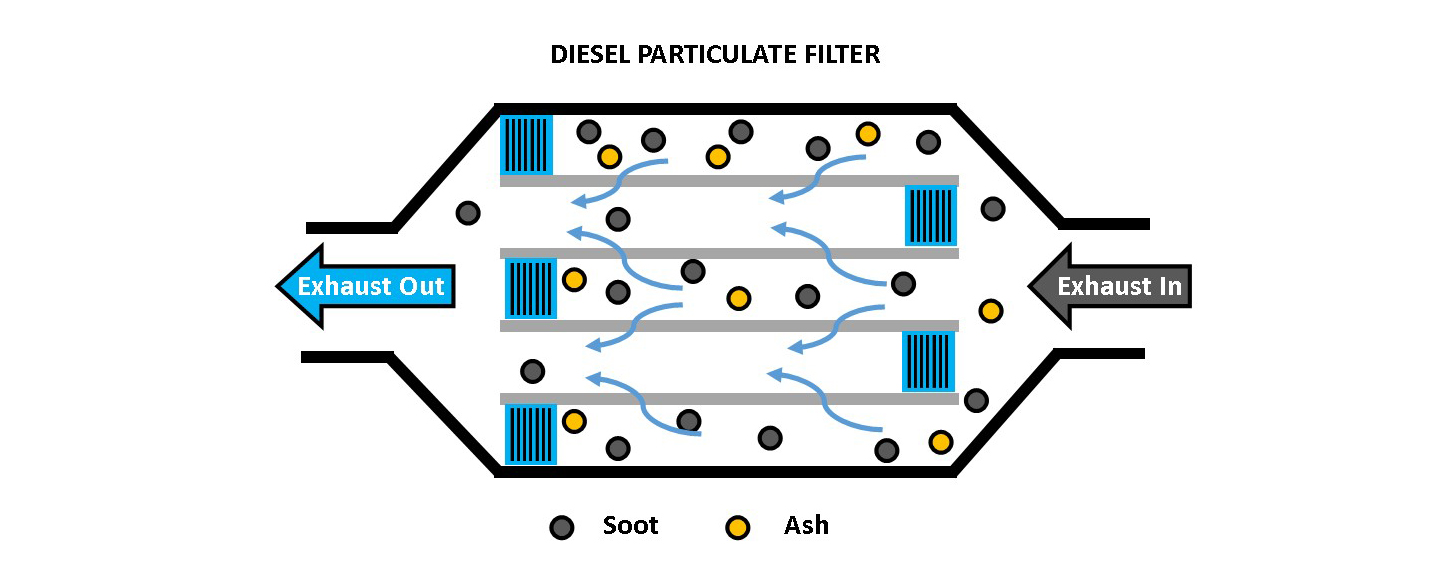

What are Diesel Particulate Filters (DPFs)?

DPFs are devices fitted to the exhaust systems of modern diesel vehicles to reduce emissions and meet emission standards. They achieve this by trapping the Soot and Particulate Matter from the exhaust gasses while the gasses pass through the system.

With any type of filter, a DFP needs to be cleaned regularly to function properly. DPFs have been in common use in passenger cars and light commercial vehicles for many years and continue to be the subject of environmental protection laws.

Problems with Diesel Particulate Filters

A build-up of soot will affect the performance and fuel economy of the vehicle and left unattended this will result in a blocked DPF which may also cause very expensive damage to other engine components. A blocked DPF is potentially dangerous as it can cause overheating in the exhaust system and present a fire risk. Most new vehicles have a ‘Limp Home’ mode which significantly reduces power to the engine.

For regeneration to take place the vehicle should be driven regularly at some speed on open roads e.g. motorways at around 2500 RPM for up to 30mins at least once a month.

Diesel vehicles used in urban areas or on short stop start journeys do not get the chance to heat up sufficiently and cannot carry out the full regeneration process.

Over time ash and soot will build up and block the DPF. For this reason, a DPF is classified as a serviceable item by the OEM and are likely not covered under warranty. DPF systems therefore need to be maintained properly.

Similar issues confront Engine Gas Recirculation (EGR) Coolers and Valves, Catalytic Converters, Diesel Particulate Filters (DPFs) and Diesel Oxidation Catalysts (DOCs).

Problems with EGR coolers, EGR valves, Diesel Particulate Filters, Catalytic Converter and Diesel Oxidation Catalysts are caused by ash type build up clogging the equipment and causing failures. The result is the environment is polluted and the vehicle’s performance drops.

Most OEMs simply swap the clogged unit for a new one, the cost of which is often horrendous. A refurbished and cleaned unit will perform just as well for a fraction of the cost of a new one.

Regular maintenance is recommended and keeping EGR coolers, EGR valves, Diesel Particulate Filters, Catalytic Converters and Diesel Oxidation Catalysts clean is vital to avoid unwanted issues and maintain peak performance.

Ultrasonic Cleaning of vehicle components

Fluid Dynamics Ultrasonic cleaning system is the ideal solution for the cost effective, safe and effective cleaning of all these components.

If you have a faulty EGR cooler, EGR valve, Diesel Particulate Filter, Catalytic Converter or Diesel Oxidation Catalyst, can avoid the expense of replacing it with a new one by having it professionally cleaned and refurbished to get you back on the road.

In order to adhere to environmental standards and to reduce impact on the environment, EGR coolers, EGR valves, Diesel Particulate Filters, Catalytic Converters and Diesel Oxidation Catalysts need to be kept clean. If they wear down or not work properly they may also need to be replaced.