Ultrasonic Cleaning Features

Large Tank Capability:

At Ultrasonic Cleaning Services we use Cavitation bubbles induced by high frequency pressure (sound) waves to agitate a liquid. The agitation produces high forces on contaminants adhering to substrates like metals, plastics, glass, rubber, and ceramics. This action also penetrates blind holes, cracks, and recesses.

- Huge 2600L x 1200D x 750W tank

- Over 250 Powerful Transducers

- 7 Ultrasonic Generators

- 2 Tonne Purpose-Built Crane

- Perfect for Components and Machinery

- Suitable for most Metal and Plastic

- Non-destructive Safe Cleaning

- Environmentally Safe

Ultrasonics is world’s best and safest

practice when it comes to cleaning

metal & plastic equipment.

Ultrasound is energy in the form of a wave motion which is above the maximum level of audible sound. This energy is transmitted to the cleaning solution via a bank of transducers underneath the machine. The result of this process is termed cavitations, tiny bubbles of vaporised liquid which explode when they reach a high pressure. Cleaning takes place as shock waves dislodge soil, grease and oil from the surface of the contaminated articles placed in the solution filled tank.

Safely Cleans Almost Any Surface:

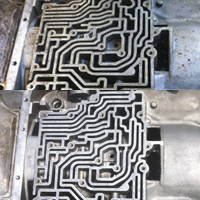

Most hard, non-absorbent materials (metals, plastics, etc.) are suitable for ultrasonic cleaning. Our bath is one of the largest in Australia and suitable for machinery, engines and transmissions. Ideal candidates also include smaller electronic parts, cables, rods, wires and detailed items, as well as objects made of glass, plastic, aluminum or ceramic.

Removes:

- Rust

- Grease

- Oil

- Scale

- Ink

- Epoxies

- Glues

- Swarf

- Grime

- Food

- Carbon

- Dirt

- Corrosion

- Filings

- Carbon

- Algae

- Fungus

- … more.

Example Equipment:

- Cylinders

- Transmissions

- Pall rings

- Throttle bodies

- Manifolds

- Filters

- Flame Arrestors

- Food processing

- Hydraulic parts

- DPFs

- Bearings

- Heat exchangers

- Solid state

- Aircraft parts

- Sumps & pumps

- Engine blocks

- EGR Coolers

- … and more.

Industry Experience:

- Aviation

- Construction

- Marine

- Food Services

- Manufacturing

- Transport

- Mining

- Industrial

- Defence

- Building

- Industry

- Power & Gas

- Mechanics

- Maritime

- Trucks & Buses

- Farming

- Agriculture

- … and more.

Bubbles Clean Heavy Duty Industrial Machinery:

In an ultrasonic cleaner the component/part is placed in a chamber containing a suitable solution (either aqueous or organic depending on required application.) In aqueous cleaners, the chemical added is a surfactant (eg- laundry detergent) which breaks down the surface tension of the water base. An ultrasound generating transducer built into the chamber, or lowered into the fluid, produces ultrasonic waves in the fluid by changing size in concert with an electrical signal oscillating at ultrasonic frequency. This creates compression waves in the liquid of the tank which ‘tear’ the liquid apart, leaving behind many millions of microscopic ‘voids’ or ‘partial vacuum bubbles’ (cavitation). These bubbles collapse with enormous energy; temperatures and pressures on the order of 5,000 K and 20,000 lbs per square inch are achieved; however, they are so small that they do no more than clean and remove surface dirt and contaminants. The higher the frequency, the smaller the nodes between the cavitation points, which allows for cleaning of more intricate detail.